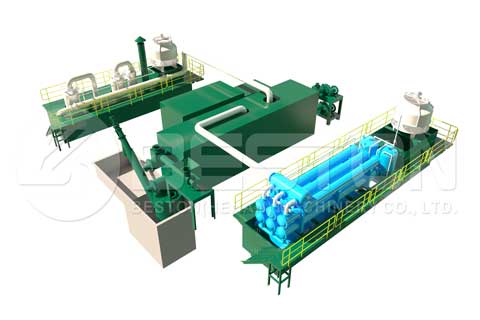

Continuous Pyrolysis Plant is very famous among most investors more especially those who have used it. It is able to dispose or process various materials like plastic, oil, tire oil sludge among others of huge quantity of up to 20 tons. The process on the machine is systematic and automatic in discharging and feeding the slag in a continuous way without having a stop. This is a very profitable investment plan because its working is efficient and convenient.

Operation description of the continuous pyrolysis plant

The operation of this plant can be well described in the various stages that are involved and the continuous pyrolysis plant design is made for the purpose of waste recycling and energy saving. This includes

a. Pre-treatment

The waste materials are always supposed to be treated even before entering the pyrolysis process. For this to be done there is a need to have a tire shredder machine that is used to crush the tires into smaller pieces of around 40mm. if there are plastics that are rigid and are of large sizes they are too needed to be crushed. Those wastes from the medical areas are also disinfected.

b.Raw material feeding

Having pretreated the waste raw materials, feed all of them to the reactor. Once they the reactor has been feed, it is sealed and the inlet doors closed in order to make sure that there is no escape of any gas from the reactor. This step is usually done in a caring way in order to avoid any leakage.

c.Pyrolysis

The pyrolysis reactor is heated using either fuel gas, charcoal or any other heat source. The reactor is heated until it reaches 250 degrees when the oil gas will be formed. The step then paves the way for the condensation stage. You should notice that the reactor designs of the continuous pyrolysis plant and small pyrolysis plant are a little bit different, click it to learn more.

d.Condensation stage

Once the oil gas is formed, it is directed to the condensation stage where it is converted into liquid oil. The condenser that is used in this is made in a way that it improves the oil efficiency and also makes the maximum conversation or condensation of the oil gas that enters there.

e.Wasted gas recovery

In the condensation chamber, not all the oil gas is condensed and therefore there is some which may go out and it is good to be brought back. There is a way in which it is made to ensure that there is a secure way in which the gas is brought back onto the condensation chamber safely. In order to save energy use within the system, the wasted gas is directed to the reactor and heated again before it is condensed.

f.Discharge

The only discharge is the steel and carbon black which are automatically discharged while the other waste materials are feed in the reactor.

Characteristics of the continuous pyrolysis plant

·The pre-treatment is required。

·Steel wire and carbon black are automatically discharged while the other waste materials are feed on the reactor. The full pyrolysis process can be achieved through feeding of the raw materials on one end and the other end is used to automatically discharge carbon black and steel wire.

·The pyrolysis process is able to work for 24 hours a day without having a stop. This helps in improving the efficiency and save of manpower that is required for the complete process.

·The reactor of the pyrolysis plant is very stable with no rotary and this helps in making the process react so quickly. It’s from this design that makes the whole process more efficient and ideal.

In addition, as one of the professional pyrolysis machine manufacturers, we can supply customized services for all the customers.

Advantages of continuous pyrolysis plant

- It adopts the use of the automatic tube condenser that helps in the whole condensing process and hence improves the efficiency process.

- The reactor is stable with no rotary on it and hence this increases the pyrolysis process. It also makes the whole process manpower saving and use of low energy in the process.

- The design is made in a way to protect both the work and environment. The proper casing and sealing that is done are meant to ensure that the workers and the environment have been protected.

- It can also work for 24 hours a day without stopping or cooling down before one starts the second batch if its there.

If for real you are in need of good investments with low labor and the dispose of your large waste, then Continuous Pyrolysis Plant is the best option for you. All you need is to visit us so that you can see how our technology is working and how helpful we will be for you. We provide the best services to our customers.