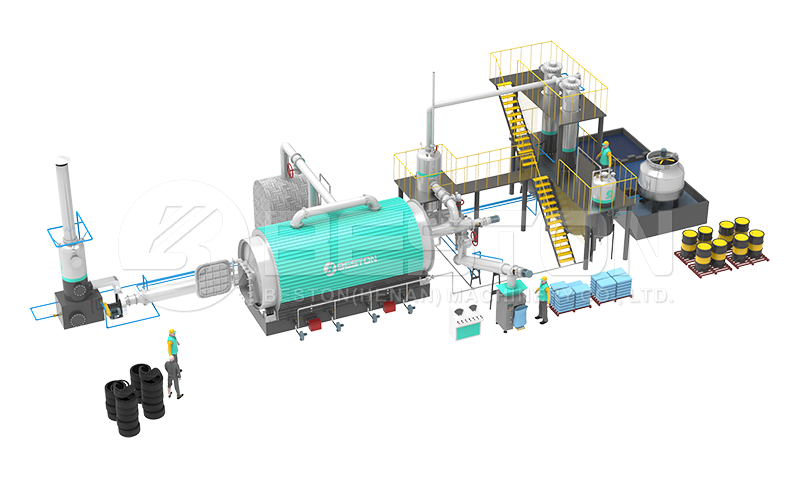

When you need to process waste so it can be turned into oil or carbon black you are going to want to invest in a pyrolysis plant. The pyrolysis plant allows you to turn waste tyre, rubber, plastic into something you can use and the price is going to be affordable. The plant can be used in many ways and it provides you with an affordable way to get a lot of work done. The most important thing is the pyrolysis plant cost.

The machine takes biomass and heats it to a very high temperature. Once the materials are heated they turn into oil or charcoal. The machine can process a lot of biomass and it does so very efficiently so you don’t need to spend a lot of money running the machine.

The plant meets all emissions standards and it provides your company with a green way to process waste. The machine is economical and it is also CE and ISO certified. The continuous pyrolysis plant allows you to run the machine 24 hours a day. This ensures that you make more money and it also ensures that you don’t have to keep stopping the machine to cool off the reactor.

The materials that go into the machine need to be broken down into smaller pieces. They also need to be dried. You might need to use a shredding and drying machine to dry the materials so they don’t have more than a 15 percent moisture content.

When it is time to start the machine the materials need to be loaded into the machine and then you just turn it on. The plant has two layers in the heating chamber which ensures that the heat stays contained where it is supposed to be. The heat is also recycled which makes the plant affordable to run. The plant is very affordable and it can help you in multiple ways. Here is a waste tyre recycling plant video from Beston Machinery.

When you want to buy a machine you need to know how much charcoal you need to make. This will help you choose a machine that is the right size. The price of the machine will depend on how large the machine is and how much it can process.

The manufacturer should offer after sales service and they should also offer training and installation. It is important that your crew knows exactly what they need to do and they also have to follow the right safety procedures. The machine is safe because of the double layer heating technology but you still have to be careful with the machine.

The machine allows you to process many tons of waste. This takes the biomass out of the environment which is good for the environment. The machine meets emissions standards and it doesn’t use a lot of energy to run. When you choose this machine you are helping the environment and you can also make money. The machine is capable of running 24 hours straight and it provides you with an affordable way to get a lot of work done and make more money.