Plastic pollution has become one of the most pressing environmental issues of our time. With millions of tons of plastic produced annually, and a significant portion ending up in landfills or the ocean, the need for sustainable solutions is more urgent than ever. Traditional recycling methods have shown limited success due to the complexity and contamination of plastic waste streams. As a result, innovative methods such as plastic pyrolysis technology are gaining traction for turning waste into value.

Understanding Plastic Pyrolysis Oil

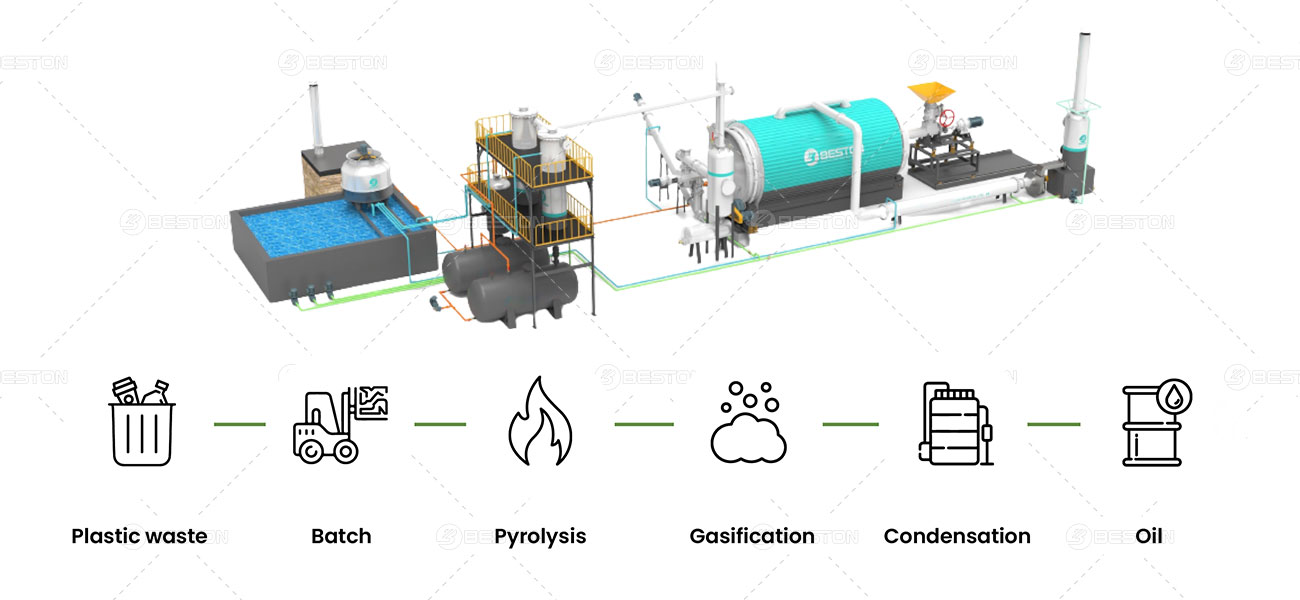

Plastic pyrolysis is a thermochemical process that breaks down polymers at high temperatures in the absence of oxygen, converting them into useful by-products, including gases, char, and pyrolysis oil. This oil, commonly referred to as plastic pyrolysis oil, resembles crude oil and can be refined or directly used in several industrial applications. As a renewable alternative, it offers a dual benefit—waste reduction and energy recovery.

Applications of Pyrolysis Oil in the Chemical Industry

In the chemical sector, pyrolysis oil serves as a feedstock that can substitute fossil-based raw materials. It can be further processed through distillation or catalytic cracking into fuels, waxes, or chemical building blocks like olefins and aromatics. These intermediates are essential in the manufacture of plastics, synthetic rubber, resins, and solvents. The integration of plastic-derived pyrolysis oil into the chemical supply chain helps create a circular economy, where waste materials are reintegrated into the production cycle.

Advantages for Petrochemical Companies

Petrochemical companies are constantly exploring ways to reduce their carbon footprint while maintaining production efficiency. Utilizing plastic pyrolysis oil aligns with their sustainability goals. It reduces reliance on virgin fossil feedstocks, thereby lowering greenhouse gas emissions. Moreover, it offers a cost-effective alternative due to the abundance of plastic waste and lower collection and processing costs, especially when using a high-performance plastic to oil machine.

Environmental and Regulatory Incentives

Governments and environmental agencies are increasingly supporting alternative recycling methods through subsidies, carbon credits, and legislative mandates. The EU’s Waste Framework Directive, for example, emphasizes energy recovery and sustainable material management. Countries that adopt beston group pyrolysis technologies may benefit from tax reliefs and green energy incentives, enhancing the economic viability of adopting such solutions.

Technological Innovations on the Horizon

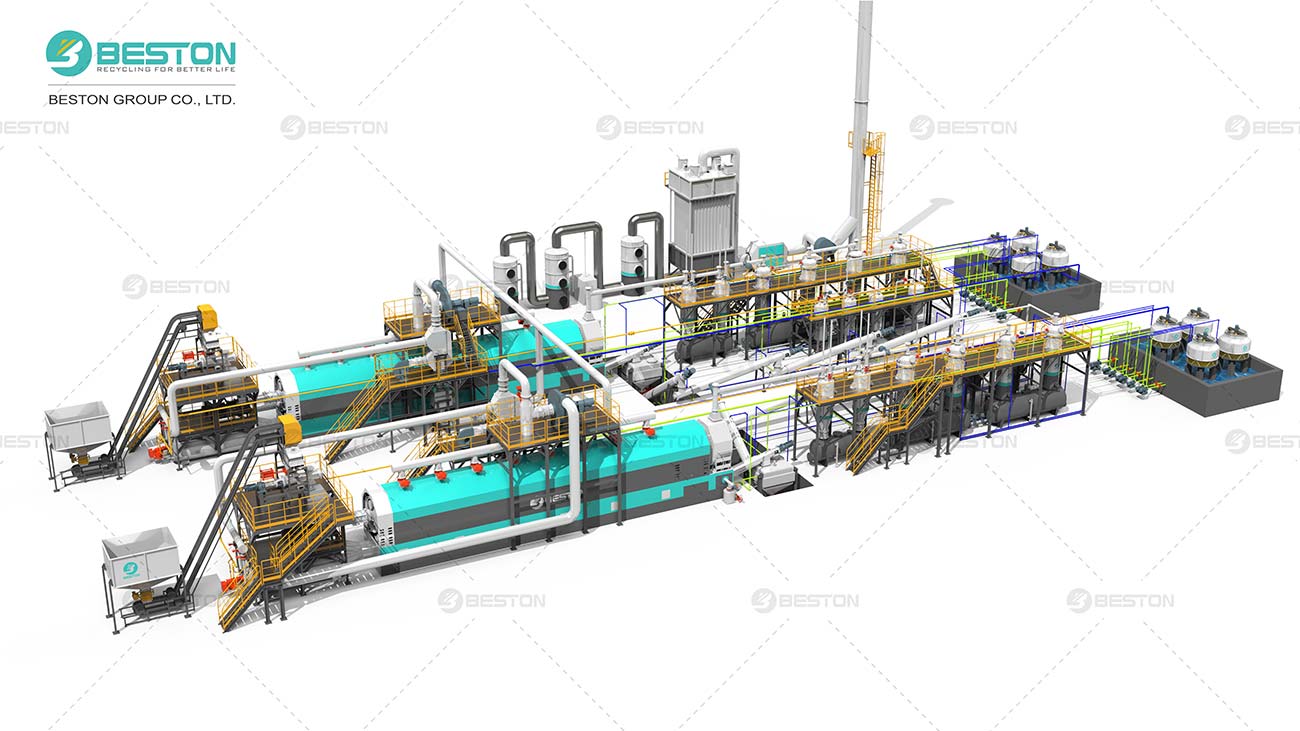

To address these challenges, ongoing research is focused on improving reactor design, feedstock pre-treatment, and catalyst development. Modular and scalable plastic pyrolysis plant systems allow industries to process waste near the source, reducing transportation costs and carbon emissions. Innovations in AI-driven monitoring and process optimization also ensure better yield and quality control.

Market Potential and Industry Interest

Market analysts project significant growth in the plastic pyrolysis industry over the next decade. Large-scale chemical producers and energy companies are investing in pilot projects and joint ventures. With more stringent recycling targets and rising crude oil prices, pyrolysis oil stands out as an economically and environmentally viable resource. Organizations that deploy a robust plastic to oil machine are better positioned to capture this emerging market.

Contributing to a Circular Economy

The use of plastic pyrolysis oil supports the global movement toward circularity. Instead of a linear approach—produce, use, and discard—pyrolysis allows for continuous material reuse. This not only mitigates environmental degradation but also fosters innovation in waste management and sustainable chemical engineering. Solutions offered by leaders like beston group pyrolysis are crucial in bridging the gap between waste and resource.

Conclusion

Plastic pyrolysis oil presents an exciting opportunity for the chemical industry to embrace sustainability without compromising on performance or profitability. With advancements in technology and growing environmental awareness, the adoption of this alternative feedstock is set to rise. Companies that invest early in continuous plastic pyrolysis plant solutions and integrate circular principles into their operations will stay competitive.