The manufacturing process of egg trays involves an egg tray production line. These activities involve processing waste or recycled paper through a sequence of processes to arrive at the finished product, better known as egg trays or egg cartons.

Egg Tray Manufacturing Process

After completing the preparation work, you are ready for the formal manufacturing process. There are 4 steps involved to manufacture egg trays(máquina para hacer bandejas de huevos). This includes pulp preparation, molding, tray drying, and the final product packaging.

Egg Tray Pulping System

The preparation of the pulp occurs in the egg tray pulping system. During this stage, the waste paper will be broken down, stirred, and then pulped.

Pulp Preparation Process

The recycled or waste paper is put inside a water-powered pulper(máquina para fabricar cubetas de huevos). The blades start rotating and after around 30 to 40 minutes the materials are broken down into pulp due to the friction and shear of the blades and the stream of water. The pulp then flows into a storage tank through a pipeline.

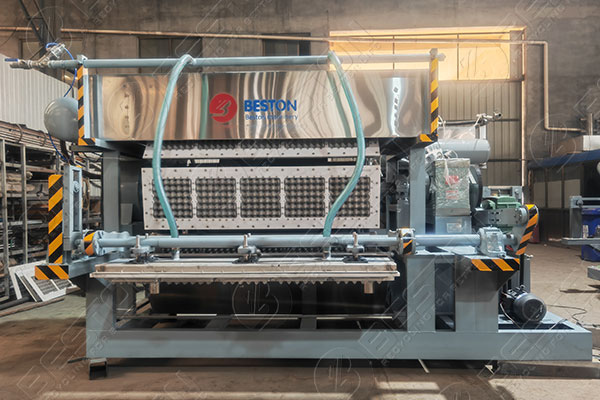

The Egg Tray Molding System

The molding of the egg trays is made in this system. This process involves pressing the pulp to form wet egg trays.

The pulp that was prepared in the pulping-system will be diluted to a specific concentration. From here, the pulp will be pumped directly into a pulp box to prepare the materials for pressing.

From here a mechanical plate that forms part of a forming mold sinks and will be completely submerged in the wet pulp. Under a suction effect caused by a vacuum device positioned on the outside of the forming-mold, the pulp will absorb into the mold. After a time frame of between 5 and 10 seconds, the mechanical plate will withdraw from the pulp.

Due to the hollow structures of these egg tray molds, the water content of the pulp will be drawn from tiny holes and will be distributed evenly over the surface of these molds. The pulp fibers will then adhere and gather over the surfaces of the molds. According to different shape molds, a layer of fiber that resembles the shape of egg trays along with a thickness of around 2.5 mm will be formed. This is the process used to form wet egg trays(https://www.bestoneco.com/maquina-para-hacer-cartones-de-huevos-en-colombia/). These wet trays do not have a load-bearing capacity, which is why they need to be conveyed to the next step of the process, which involves drying.

Egg Tray Drying System

The wet trays now go through a process in a drying system. The drying system for egg trays and egg cartons plays a vital role in the production of egg trays. Once the wet products have been dried in these drying systems, the final product is easy to obtain. Once the egg trays(bestoneco.com) are dry, the fibers in the pulp are given a supporting effect.