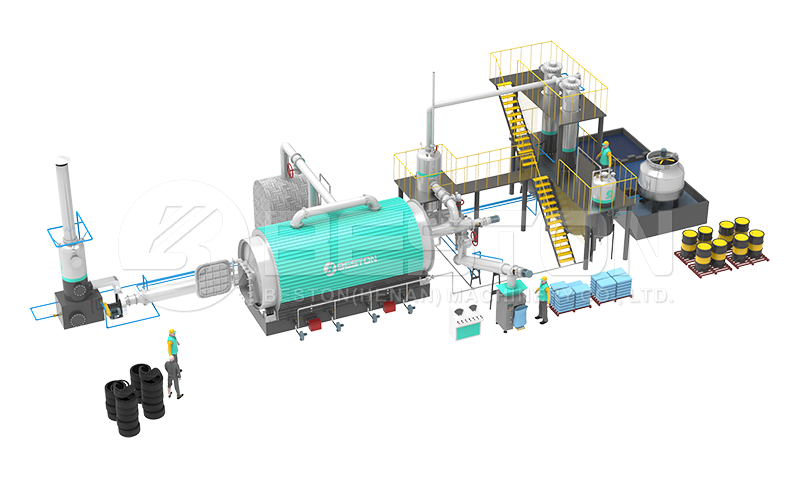

A waste tyre pyrolysis plant is an eco-friendly piece of machinery that is used to recycle used tyres into marketable materials. Such a plant provides an environmentally-friendly alternative to simply incinerating waste tyres or throwing them into landfill sites. The marketable materials produced by a pyrolysis plant are fuel oil, carbon black, combustible gases and steel wires.

Those who live in modern societies will know that owning a car is now a necessity for many employment opportunities. Unfortunately, as increasing numbers of cars are needed, the disposal of increasing quantities of used tyres has become a big problem for many areas. Fortunately, waste tyre pyrolysis plants are now becoming more commonplace around the world, which means used tyres can easily be recycled into profitable materials. Pyrolysis reactor manufacturers export their products to countries all over the map including Romania, Nigeria, India, Sudia Arabia, Australia, Indonesia, Philippines, UK, Brazil, South Africa, Argentina and more.

There are dozens of tyre pyrolysis plant manufacturers in operations, and one of the most well-known is Beston. All of the manufacturers in the industry produce different models of plants, so companies can easily source machinery that matches their needs. Those who want to start a small-scale tire recycling plants, for example, are probably going to want to look at pyrolysis plants that utilize batch operating systems. Meanwhile, those looking to start a large-scale recycling factory that operates 24/7 will need to explore semi-continuous and continuous tyre pyrolysis plant options.

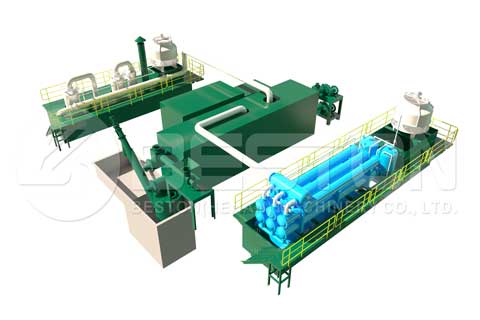

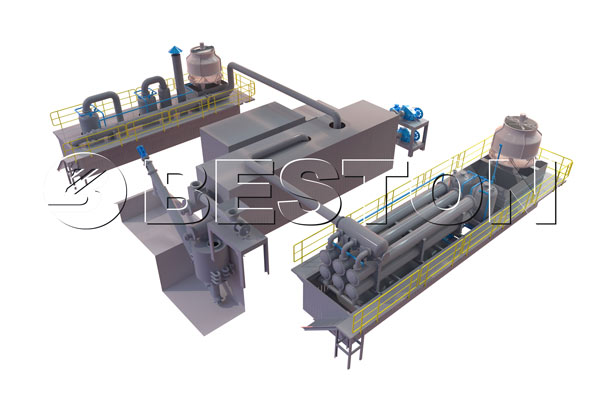

A semi-continuous pyrolysis plant is equipped with an auto-feeder which automatically feeds waste tyres into the main reactor. Meanwhile, a plant that has a batch operating system requires a labor force to manually feed materials into the reactor. Both semi-continuous and batch system plants have 360-degree rotary reactor designs. Wanna learn more information about the designs for different types of the plant, you can click here.

A continuous pyrolysis plant, also named automatic pyrolysis plant, has a horizontal reactor design, which makes it much more stable. This type of plant can operate 24/7 as the reactor does not require a cool-down period between batches. As a consequence, continuous plants can process up to 24 tons of waste tyres each day.

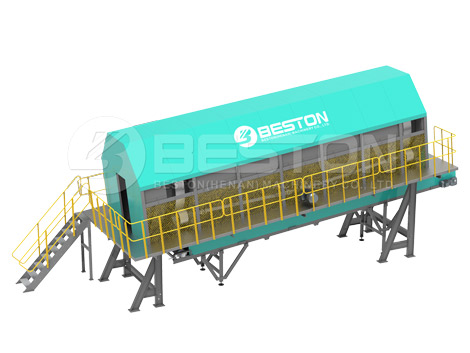

It is important to note that all pyrolysis reactors require the waste tyre raw materials to be cut into small pieces before they enter the main chamber. This means tyre recycling plants need to invest in tyre shredder machines. You can find plenty of these machines for sale online.

The end materials produced by a waste tyre recycling pyrolysis plant are pyrolysis oil, black carbon, steel wire, and combustible gases. All of these materials can be sold to different industries in various forms for big profits. Pyrolysis oil, for example, can be refined into gasoline and diesel in a distillation machine. Black carbon can be mixed with clay and transformed into construction bricks. Steel factories meanwhile are always looking to buy steel wire from tyre recycling facilities.