Thermal desorption is a process used to separate and recover volatile organic compounds from a sample. This can be done through thermal desorption unit price, which is an instrument designed for this purpose.

The Process

The process of thermal desorption involves heating the sample, usually at a temperature of about 250-450 degrees Celsius, to desorb compounds. The gases and vapors released during the process are then collected in a sample tube or canister. The efficiency of thermal desorption depends on the condition of the sample and the temperature used. Generally, the higher the temperature, the higher the efficiency. However, the quality of the sample is also important, as too high of a temperature can damage it. To ensure the best conditions for desorption, the sample is first conditioned through a process called “drying”, which involves heating the sample in an inert atmosphere.

More details: https://bestonasia.com/small-pyrolysis-machine/.

Use of Thermal Desorption

Thermal desorption units are used in various industries, such as industrial, environmental, and food production. In industrial applications, thermal desorption is used for quality control, as it can detect any volatile contaminants present in the sample. In environmental applications, it can be used to detect the presence of volatile organic compounds in the atmosphere. Finally, in food production, thermal desorption is used to measure the number of volatile compounds in food products, thus ensuring their safety and quality.

Thermal desorption pyrolysis reactor is a process that is becoming increasingly important in many industries. It is used to separate and concentrate volatile organic compounds (VOCs) from non-volatile materials. It is also used to purify and process materials such as hazardous waste and hazardous materials. This process is becoming increasingly necessary due to the growing need for environmental protection and waste management.

It can also be used to purify and process materials that have been contaminated by VOCs.Thermal desorption is also beneficial in industrial applications. It can help to improve the safety of working environments by reducing the number of hazardous chemicals that could be released into the air. Additionally, it can help reduce the cost of waste management and disposal, as it can often be used to separate and concentrate VOCs from non-volatile materials.

Waste Control

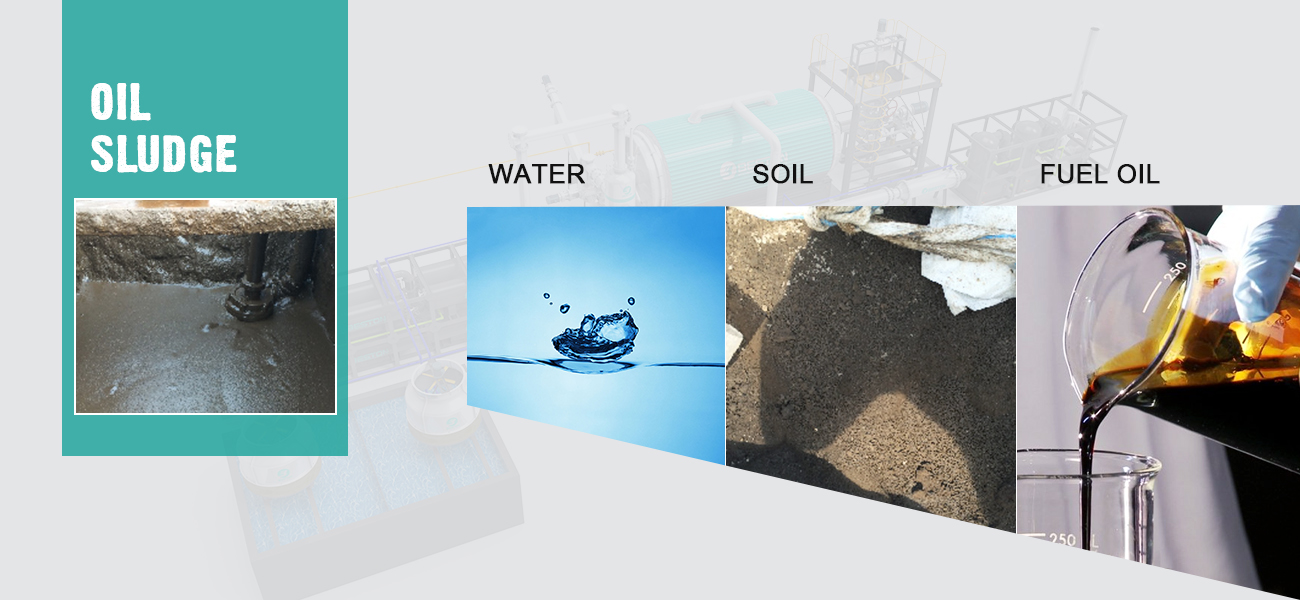

Thermal desorption is an important process in the field of waste control. It is a method used to remove volatile and semi-volatile compounds from a variety of solid and liquid materials. The process involves heating the material to a temperature where the compounds will be vaporized and then collecting these compounds by condensation. This process is effective in removing a variety of contaminants and pollutants from a variety of substrates, including contaminated soil and water.

Thermal desorption can be used as a stand-alone process or as part of larger continuous pyrolysis equipment. It is also effective in removing pollutants from wastewater, such as oils and greases, which can be hazardous if released into the environment. Thermal desorption can be used to reduce the toxicity of waste materials, making them more suitable for disposal. In addition to waste control, thermal desorption has a variety of other applications. It is used in the petrochemical industry to purify crude oil, as well as in the food and beverage industry to remove unpleasant odors and tastes. It can also be used in manufacturing.