Do you want to know more about cost of buying an egg tray machine? Do you want to make sure that your egg tray manufacturing business is profitable? Do you want to get the maximum return on your investment in an egg tray machine? If the answer to these questions is yes, this is the article for you. In this article, we are going to discuss the cost of buying a tray making machine and how you should go about buying this machine in order to get the maximum return on your investment.

Buying an Egg Tray Machine

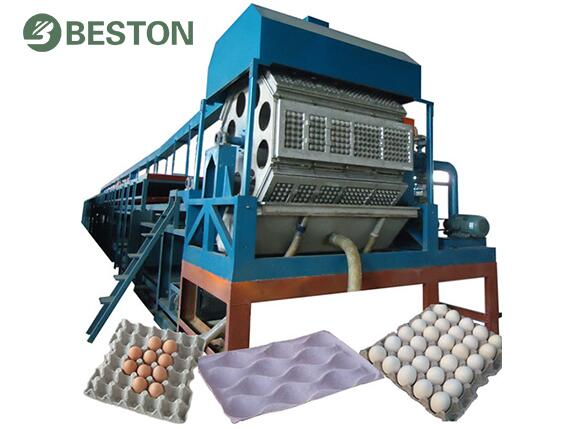

Before you move ahead with buying the machine(máquina moldeadora de Pulpa de papel), you should know about the process of making these trays. In the first step which is known as the pulping face, recycled paper is mixed with water in order to get the raw material. Once this raw material is prepared, it is then fed to the machine in order to mound it into the desired formation. Needless to say, many different types of molds can be used for making different styles and shapes. In most cases, egg tray is used but you should be able to make different types including fruit trays as well as shoe supports by switching the molds.

The last process is solidification of the trays in order to make sure that they remain tough and sturdy once they are completely dry. In many cases, natural air drying process is used for drying. Keep in mind that there are other methods of drying but it will depend on the machine as well as some other parameters.

When it comes to cost of an egg tray machine(https://www.bestoneco.com/maquina-de-hacer-maples-de-huevo/), it depends on a lot of parameters. One of the most important parameters is whether you want to buy a completely manual, a semiautomatic or a completely automatic tray making machine. Needless to say, the manual machine is going to cost less as compared to a semiautomatic machine whereas a fully automatic machine is going to cost the highest.

The manual machines are cheaper but you also need to take into account the fact that these are labor intensive and labor costs a lot of money. Also, manual machines are unable to match the quantity of trays that can be manufactured by a semiautomatic or fully automatic machine. However, the choice between these three options depends solely on the market for trays in your location. For cheaper price, choosing the right supplier is also very important. Beston Group maybe a good choice for you.

If you are only going to sell a small number, there is no point in investing in a fully automatic machine as you just won’t be able to sell the number of trays produced by an automatic machine. These automatic machines are suited for bigger factories that have huge requirements. For instance, an automatic machine is capable of making more than 7000 pieces of trays in one hour. It does not make sense for a small family owned business.

Another important thing you need to pay attention to is the flexibility offered by the tray making machine(https://www.bestoneco.com/btf-4-4-maquina-de-bandeja-de-huevos-en-oman/). Ideally, you should be able to change the mold and manufacture different kinds of trays depending on the requirements of your buyers. Therefore, pay close attention to specifications and make sure you buy only a flexible machine.

As far as the overall cost is concerned, you also need to take into account availability of spare components as some components might break down with time due to wear and tear. If these components cost a lot of money or are not available easily, you might suffer losses. Therefore, in addition to initial cost of the machine, you should also consider the operational cost and operational risks.

Overall, investment in a tray making machine is good business but you need to keep the above mentioned tips in mind in order to turn a profit in this business.