Introduction

Overview of Coconut Processing

Coconuts, often hailed as the “tree of life,” have been integral to various industries. From culinary uses to skincare, every part of the coconut finds its purpose. However, it’s the coconut shell that has gained renewed attention with the development of coconut shell charcoal making machines.

Significance of Coconut Shell Charcoal

Coconut shell charcoal holds immense value due to its high carbon content and low ash content. It has become a sought-after material in various industries, prompting the need for efficient and advanced methods of production.

Evolution of Coconut Shell Charcoal Making Machines

Historical Background

The journey of coconut shell charcoal production dates back to ancient times when traditional methods involved manual charring. However, the modern era has witnessed a transformative evolution, with the integration of cutting-edge technologies.

Technological Advancements

Recent years have seen a surge in the sophistication of coconut shell charcoal making machine. Innovations in engineering have led to machines that are not only efficient in production but also environmentally friendly. The evolution is not just a leap in technology but a stride towards sustainable practices.

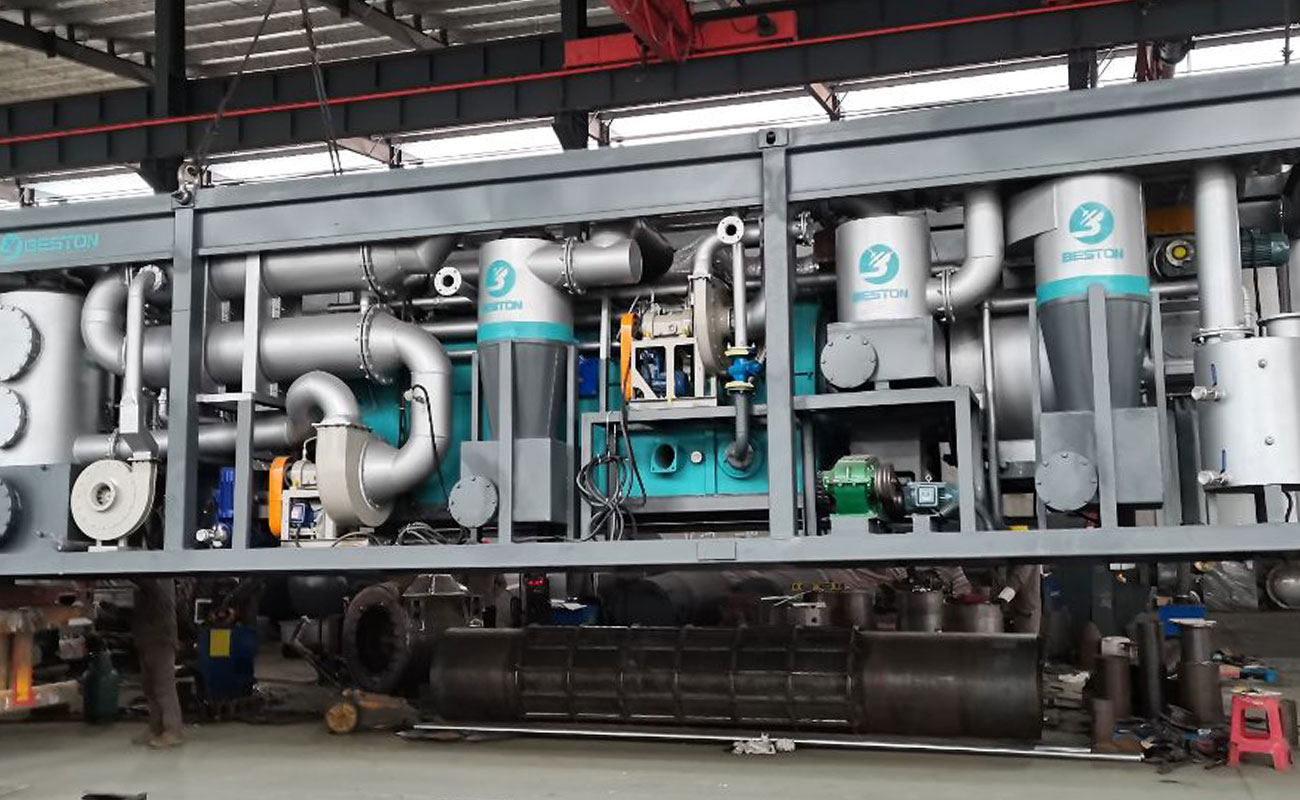

Key Components of Modern Machines

Pyrolysis Chamber

At the heart of the coconut shell charcoal making machine lies the pyrolysis chamber. This is where the magic happens – the coconut shells undergo a process called pyrolysis, where they are heated in the absence of oxygen, transforming them into charcoal.

Gasifier Unit

Adjacent to the pyrolysis chamber is the gasifier unit. This component plays a pivotal role in converting the by-products of pyrolysis into valuable gases, which can be harnessed for various purposes, contributing to the overall efficiency of the system.

Cooling System

Once the pyrolysis and gasification are complete, the cooling system comes into play. This component ensures that the charcoal produced is ready for use by rapidly reducing its temperature. The efficiency of the cooling system directly impacts the quality of the end product.

Process of Coconut Shell Charcoal Production

Feedstock Preparation

The first step involves meticulous preparation of the coconut shells. These are cleaned, dried, and sorted to ensure uniformity in the feedstock. The quality of the feedstock significantly influences the final product.

Pyrolysis Reaction

As the prepared coconut shells enter the biochar reactor, they undergo a thermal decomposition process. The absence of oxygen prevents combustion, leading to the creation of charcoal. This controlled environment is crucial for obtaining high-quality coconut shell charcoal.

Gasification and Activation

The gasifier unit takes over post-pyrolysis, converting the by-products into valuable gases. Additionally, the activated carbon, a result of the activation process, enhances the adsorption properties of coconut shell charcoal, making it highly versatile.

Advantages of Coconut Shell Charcoal

High Carbon Content

One of the standout features of coconut shell charcoal is its impressive carbon content. This attribute makes it an ideal choice for applications where a high-carbon content is paramount, such as in metallurgical industries.

Low Ash Content

Unlike traditional charcoal, coconut shell charcoal boasts remarkably low ash content. This characteristic not only enhances its combustion efficiency but also reduces environmental impact, making it an eco-friendly choice.

Environmental Sustainability

The production of coconut shell charcoal aligns with the principles of environmental sustainability. The utilization of coconut shells, which would otherwise be considered waste, contributes to the reduction of environmental footprint.

Diverse Applications of Coconut Shell Charcoal

Metallurgical Industries

Coconut shell charcoal’s high carbon content finds widespread use in metallurgical industries. Its application as a reducing agent in metal extraction processes highlights its significance in these sectors. If you want to know more about the application of coconut shell charcoal in the metal smelting industry, please visit:https://bestonasia.com/

Water Purification

The adsorption properties of activated carbon in coconut shell charcoal make it an excellent candidate for water purification. Its ability to remove impurities and contaminants from water has led to its integration into water treatment processes.

Pharmaceutical and Cosmetic Uses

The pharmaceutical and cosmetic industries have also embraced coconut shell charcoal. Its purity and adsorption capabilities make it a valuable ingredient in medicinal and cosmetic products, contributing to the growing demand for this versatile material.

Future Trends and Innovations

Integration of IoT and Automation

The future of coconut shell charcoal production is poised for a digital revolution. Integrating Internet of Things (IoT) technologies and automation into charcoal making machine enhances precision, efficiency, and data-driven decision-making, ushering in a new era of smart manufacturing.

Research and Development Initiatives

Ongoing research and development initiatives continue to push the boundaries of coconut shell charcoal production. Scientists and engineers are exploring novel methods to further enhance the quality, efficiency, and sustainability of the process, ensuring that coconut shell charcoal remains at the forefront of eco-friendly and versatile materials.

In conclusion, the coconut shell charcoal making machine has not only revolutionized coconut processing but has also opened up new avenues for sustainable practices and versatile applications. As technology continues to advance, the future holds exciting possibilities for the coconut shell charcoal industry.