Pyrolysis technology has emerged as a powerful solution for waste management that is not only eco-friendly but also potentially profitable. If you are looking to make a significant profit while contributing to environmental sustainability, investing in a continuous tire pyrolysis plant for sale might be the perfect opportunity. In this guide, we’ll explore the advantages of this technology and what you should consider when selecting a high-quality continuous pyrolysis plant.

Why Choose a Continuous Pyrolysis Plant?

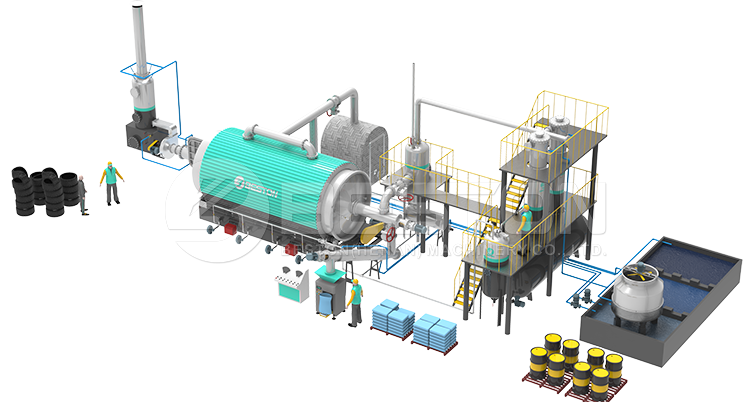

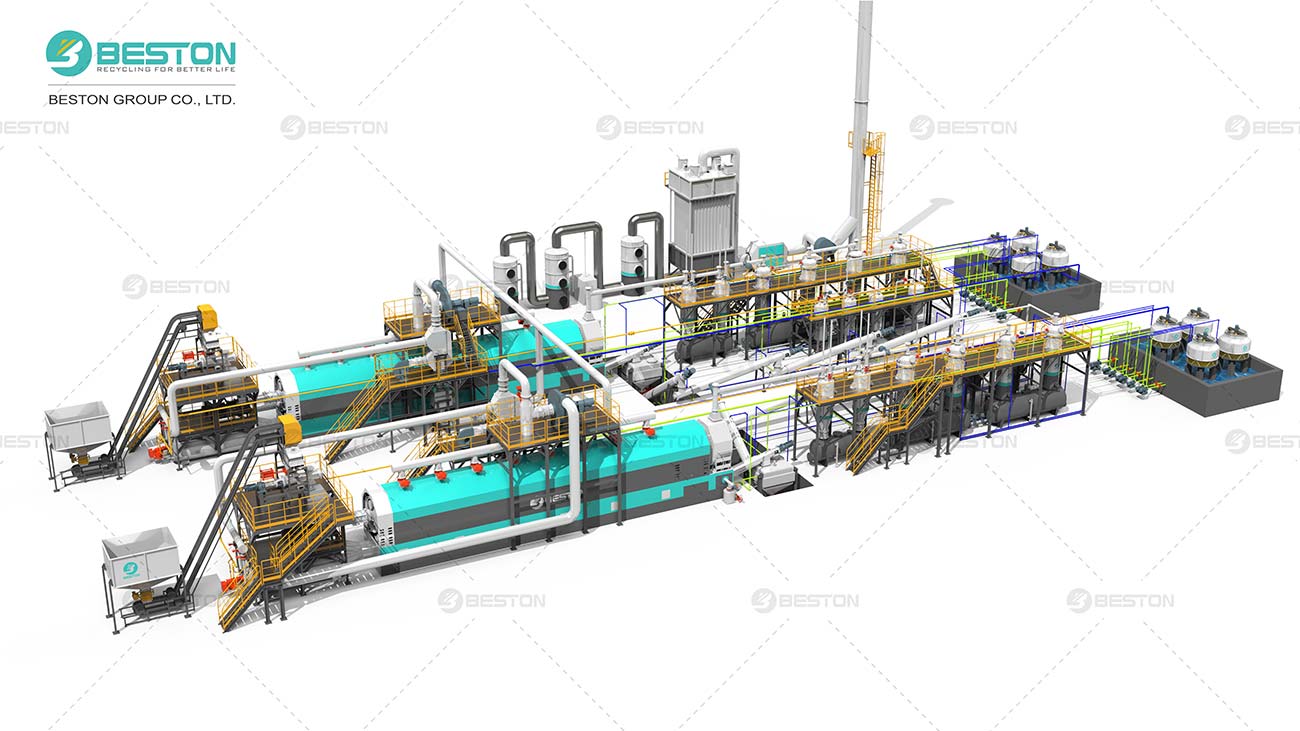

Continuous pyrolysis plant represents a significant advancement in waste-to-energy technology. Unlike batch or semi-continuous pyrolysis plants, continuous systems operate non-stop, processing materials 24/7 without the need for frequent shutdowns. This efficiency maximizes output, reduces energy consumption, and lowers operational costs, making it an attractive option for businesses looking to handle large volumes of waste while maintaining profitability.

Benefits of Investing in a Continuous Tire Pyrolysis Plant

Pyrolysis technology can convert waste rubber, plastics, and other materials into usable and profitable end products, such as fuel oil, carbon black, and combustible gas. Waste tire pyrolysis machines, in particular, offer a unique solution by recycling waste tires into valuable resources that have high market demand.

Here are some of the key advantages of investing in a continuous tire pyrolysis plant:

- Environmental Impact: Pyrolysis plants help reduce landfill waste and prevent environmental pollution by transforming waste materials into valuable resources. This contributes to a circular economy and reduces the carbon footprint.

- High Profitability: By converting waste materials into high-demand products like fuel oil, carbon black, and steel wire, businesses can generate substantial revenue. The products obtained from pyrolysis are widely used in various industries, ensuring a steady market demand.

- Energy Efficiency: Continuous pyrolysis plants are designed to operate efficiently with minimal energy consumption. The heat generated during the process can be recycled within the plant, reducing fuel costs and making the operation more sustainable.

- Low Labor Requirements: Unlike batch pyrolysis plants, continuous systems require less manual intervention, reducing labor costs and minimizing human error.

- Versatility: These plants can process a wide range of raw materials, including rubber tires, bamboo husks, wood chips, and waste plastics, allowing flexibility in sourcing raw materials.

Key Factors to Consider When Buying a Continuous Pyrolysis Plant

When looking for a continuous tyre pyrolysis plant for sale, several critical factors should guide your decision-making process:

1. Type of Waste Material

Determine the types of waste materials you have easy access to. A continuous pyrolysis plant can handle various feedstocks, such as waste tires, rubber, plastics, agricultural residues, and even certain types of medical waste. The choice of feedstock will influence the type of plant you should invest in, as different materials may require specific processing conditions.

2. Plant Capacity and Space Requirements

The plant’s capacity should align with the volume of waste you plan to process. Consider both current and future needs to avoid underestimating or overestimating your production capacity. Additionally, measure the available space in your warehouse or industrial setting where the plant will be installed. Ensuring adequate space will help you select a machine that fits comfortably within your operational environment, allowing room for maintenance and operation.

Remember, larger plants typically require more space but can handle higher volumes, while smaller plants may be suitable for limited space and lower waste volumes.

3. Budget and Cost Considerations

The cost of a pyrolysis plant varies based on its size, capacity, and features. In addition to the initial purchase price, you must consider other expenses, such as freight costs, installation, raw materials, maintenance, and operation. It is wise to establish a budget that encompasses all these factors. Conduct extensive research and compare multiple options within your budget range to find the best value for money.

4. Quality and Reliability of the Plant

Not all pyrolysis plants are created equal. Look for a plant that uses high-quality materials and components, which will ensure durability and long-term performance. Reliable manufacturers typically offer warranties and after-sales support, which are critical for maintaining smooth operation.

5. Maintenance and Operational Requirements

Maintenance is key to ensuring the longevity and efficient performance of your pyrolysis plant. Opt for a plant that requires minimal but effective maintenance. Check if the manufacturer provides training or manuals for routine maintenance tasks. Regular checks and preventive maintenance will help avoid unexpected downtime and costly repairs.

6. Safety Features

Safety should be a top priority when investing in a pyrolysis plant. Look for features such as automatic temperature and pressure control systems, emergency shutdown mechanisms, and gas leakage detectors. These features not only protect the plant and operators but also ensure compliance with safety regulations.

7. Environmental Compliance

Ensure that the pyrolysis plant for sale complies with local environmental regulations. The plant should be equipped with pollution control devices, such as dust removal systems, gas purification units, and wastewater treatment facilities, to minimize emissions and waste.

Finding the Right Manufacturer

The success of your investment greatly depends on choosing the right manufacturer or supplier. Here are some tips for finding a reliable supplier:

- Reputation and Experience: Look for manufacturers with a proven track record in the pyrolysis industry. Positive customer reviews and testimonials can provide valuable insights into the reliability and performance of their equipment.

- Technology and Innovation: Choose a manufacturer that uses the latest technology and innovation to improve the efficiency and safety of their pyrolysis plants.

- After-Sales Support: A good manufacturer should offer comprehensive after-sales services, including installation, training, maintenance, and technical support.

Conclusion

Investing in a continuous tire pyrolysis plant for sale is a smart move for businesses seeking to combine profitability with environmental sustainability. By converting waste materials into valuable products, these plants offer a sustainable solution to waste management challenges while providing a lucrative business opportunity. To ensure a successful investment, consider the type of waste material, plant capacity, space requirements, budget, quality, maintenance needs, and safety features. Most importantly, choose a reputable manufacturer who offers high-quality equipment and reliable after-sales support. With the right approach, your investment in a continuous pyrolysis plant will yield both financial and environmental rewards.