The intricate landscape of oilfield drilling invariably introduces a byproduct that poses a significant environmental challenge – oil sludge. In the pursuit of optimal remediation, the spotlight turns to an advanced treatment method: thermal desorption. This article navigates the contours of this innovative approach, delving into the nuances of the thermal desorption unit and its synergistic use of pyrolysis for efficacious oil sludge treatment.

Understanding the Oilfield Drilling Oil Sludge Conundrum

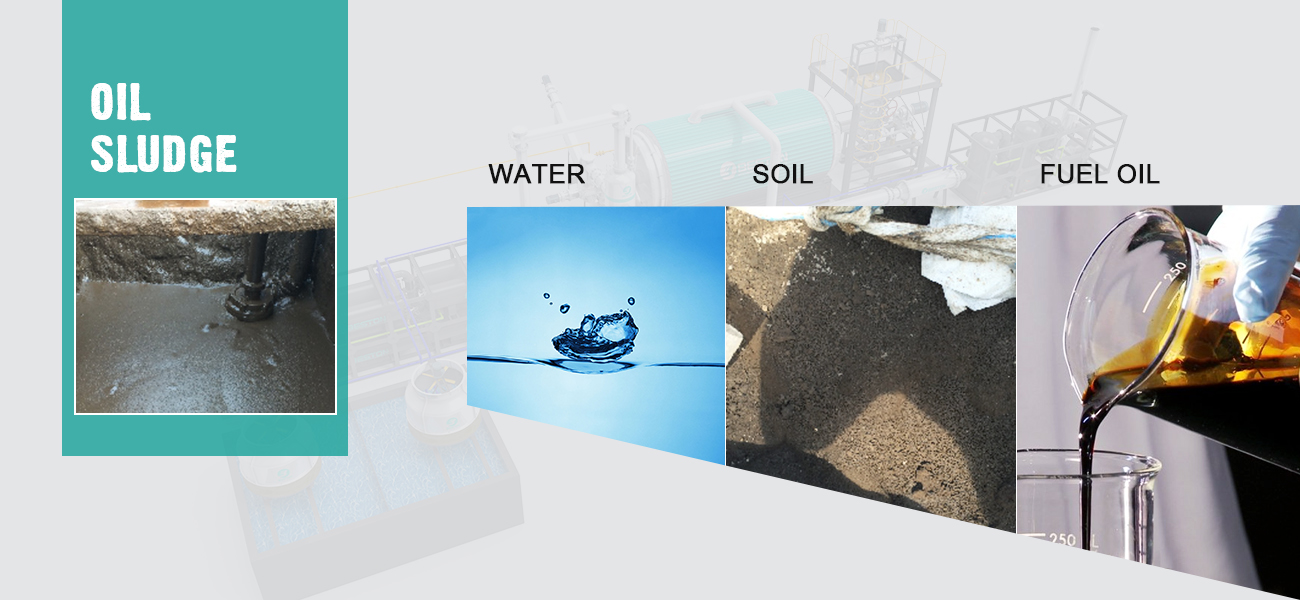

Oil sludge, a complex amalgamation of oil, water, and solid particles, is a byproduct of drilling activities in the oil and gas industry. Traditional disposal methods fall short of addressing the environmental impact of this sludge, necessitating the exploration of advanced treatment techniques.

The Challenges Posed by Oil Sludge

Oil sludge poses multifaceted challenges, from soil contamination to potential harm to aquatic ecosystems. Traditional methods like land spreading or burial often lead to long-term environmental consequences. In this context, the thermal desorption unit emerges as a beacon of sustainable remediation.

Decoding the Dynamics of Thermal Desorption

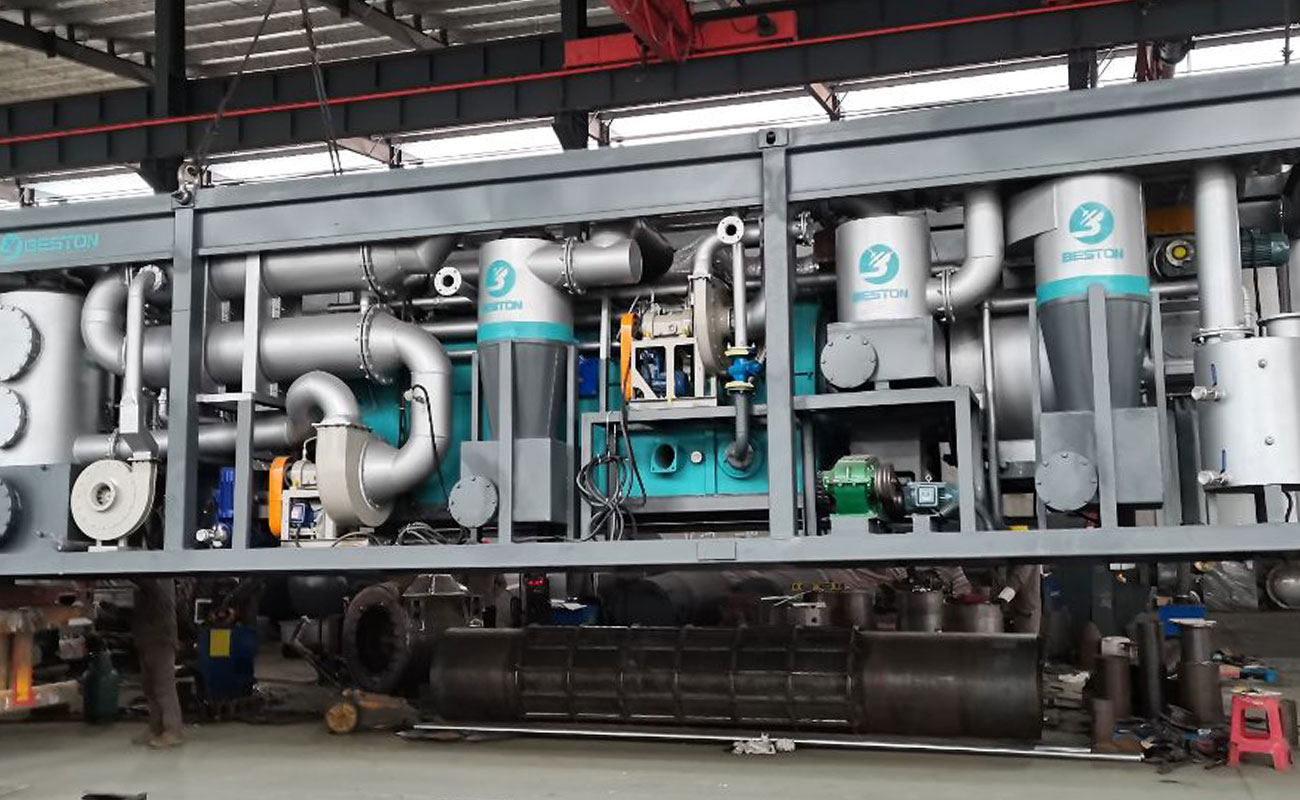

Stage 1: Introduction to the Thermal Desorption Unit

The journey of oil sludge treatment with thermal desorption begins with the deployment of a specialized system – the thermal desorption unit. This unit is engineered to facilitate the controlled application of heat, optimizing the separation of contaminants from the sludge matrix.

Temperature Precision

A hallmark of the thermal desorption unit lies in its ability to achieve precise temperature control. This is crucial as different contaminants within the oil sludge have varying volatilization points. The unit ensures that the temperature is calibrated to effectively target the separation of oil, water, and solids.

Stage 2: Pyrolysis Unveiled

At the core of thermal desorption is the process of pyrolysis. This thermochemical decomposition method involves subjecting the oil sludge to high temperatures in the absence of oxygen. This controlled environment induces the breakdown of complex hydrocarbons, separating them into their elemental components.

Volatile Organic Compounds Removal

During the pyrolysis process within the oil sludge treatment plant, volatile organic compounds (VOCs) are released. These compounds, often responsible for air pollution, are efficiently captured and can be further treated or used as a potential energy source, contributing to the overall sustainability of the treatment process.

Environmental Advantages of Thermal Desorption

Soil Remediation

One of the paramount benefits of thermal desorption is its effectiveness in soil remediation. The controlled application of heat facilitates the release of contaminants from the soil matrix, allowing for their capture and subsequent treatment. The treated soil exhibits a notable reduction in hydrocarbon content, paving the way for ecological restoration.

Water Resource Protection

In oilfield drilling, the potential contamination of water resources by oil sludge is a critical concern. Thermal desorption, through its rigorous separation of oil and water components, serves as a safeguard against water pollution. The treated water, once freed from hydrocarbon contaminants, can be safely reintroduced into natural water systems.

Technical Precision and Innovation in Thermal Desorption

Continuous Advancements in Technology

The landscape of thermal desorption is marked by continuous technological advancements. Modern iterations of the thermal desorption unit incorporate intelligent control systems, automated monitoring, and real-time data analysis. These features not only enhance operational efficiency but also contribute to a more sustainable and cost-effective treatment process.

Energy Efficiency

In the pursuit of sustainability, the latest thermal desorption units prioritize energy efficiency. Innovative heat recovery systems capture and repurpose thermal energy generated during the treatment process. This dual-purpose approach not only reduces operational costs but also aligns with the broader commitment to environmental stewardship.

Pyrolysis Reactor Designs

The reactor within the thermal desorption unit, where the pyrolysis process unfolds, undergoes design innovations. These advancements focus on optimizing heat distribution, enhancing reaction kinetics, and minimizing heat loss. The result is a more efficient and streamlined pyrolysis process within the thermal desorption unit.

Cost Considerations and Return on Investment

Initial Investment

Adopting thermal desorption as a method for oil sludge treatment involves an initial capital investment in the pyrolysis plant for sale. Factors such as unit capacity, technology specifications, and additional features contribute to the overall cost. While the initial outlay may seem significant, the long-term benefits and sustainability credentials often outweigh the upfront investment.

Operational Costs

Beyond the initial investment, operational costs play a pivotal role in the economic evaluation of thermal desorption. These costs encompass energy consumption, maintenance, waste disposal, and labor. The efficiency gains achieved through technological innovations in the thermal desorption unit can positively impact long-term operational expenses.

Return on Investment (ROI)

The economic viability of adopting thermal desorption hinges on the return on investment (ROI). Revenue streams generated through the recovery and potential reuse of valuable byproducts, such as reclaimed oil or syngas from pyrolysis, contribute to the overall ROI. The growing emphasis on sustainable practices positions the treated sludge as a valuable resource, further enhancing the economic outlook.

Challenges and Ongoing Research in Thermal Desorption

Residual Contaminant Management

Challenges persist in addressing residual contaminants that may remain after thermal desorption. Ongoing research focuses on refining treatment methods, exploring advanced sorbents, and developing post-treatment technologies to ensure that the treated sludge meets stringent environmental standards.

Scalability and Adaptability

As industries seek to adopt thermal desorption on a larger scale, considerations of scalability and adaptability become paramount. Research efforts are directed towards developing modular and flexible thermal desorption units that can cater to varying capacities and accommodate different types of oil sludge compositions. Beston China can provide you with customized solutions, just contact us.

A Sustainable Tomorrow: Thermal Desorption in Perspective

In conclusion, the adoption of thermal desorption as a treatment method for oilfield drilling oil sludge represents a paradigm shift towards sustainability. The intricate interplay of the thermal desorption unit and pyrolysis not only addresses environmental challenges but also aligns with the evolving ethos of responsible industrial practices.

As technology continues to advance, the economic viability of thermal desorption becomes increasingly compelling. The integration of intelligent control systems, innovations in reactor design, and the pursuit of energy efficiency collectively underscore the potential of thermal desorption as a cornerstone in the journey towards a cleaner, more sustainable tomorrow