As you look to go with the right thermal desorption unit, you will know it is not going to be easy to locate an option that is the real deal.

This is where a good supplier is going to make a difference and you will appreciate the value you are getting with the new thermal desorption unit.

Fast Results

The thermal desorption unit is one of those options that you will know is going to last a long time but it is also going to produce immediate results. This is key when you are hoping to optimize your setup and want things to work out as intended.

This is the real value you are going to see with the unit as soon as it is in place.

It will generate good results and you will feel confident in the value you are receiving.

Consistent

It is important to only go with a unit that is going to be consistent as soon as it is set up. When you are looking at different options, this one is not going to let you down. It will turn on and you will know the unit is going to continue to do the work that you want it to.

Premium Build

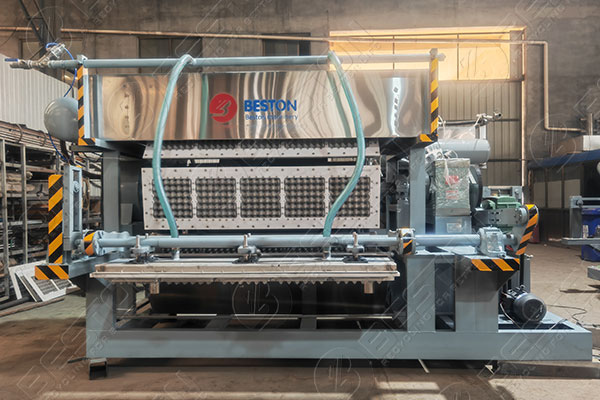

It is the premium build quality that is the first thing you are going to care about. You will want something that is well-rounded and is not going to let you down as time goes on. With all of the options that are out there, you will appreciate how long this solution lasts and the value it brings to the process. More information on Beston Group here.

This is the type of quality that will ensure your operation continues to succeed as you want it to.

Refined

The refined nature of this thermal desorption unit is something you can appreciate. It will be ready to go as soon as possible and you will start to appreciate how quickly the results come. For most business owners, it is one of those options that will simply work.

There is no reason to settle for less when you can go with this option. Check high quality pyrolysis plant for sale here.

Trusted Supplier

You are looking at a thermal desorption unit that is going to work and it will be ready to go immediately. This is important when you are thinking about the options that are out there and how they will work for you once in place.

Affordable

The thermal desorption unit is a great addition for those who want to make sure they are choosing something easy on the budget. This is a refined option that is going to work well as soon as it is set up and is going to bring a smile to your face.

If you are looking at going with a thermal desorption unit that is the real deal, you will know this is going to get the job done. You will appreciate the value that comes along with it and that is the value you are going to retain as soon as it is in place. Get pyrolysis equipment cost here.