In the realm of packaging technology, the egg tray machine, egg carton machine, and apple tray machine are often discussed interchangeably. This is largely due to their shared fundamental design and operation. While these machines produce different products—egg trays, egg cartons, and apple trays, respectively—they utilize similar processes and machinery, primarily differing only in the molds used for shaping the final products.

Common Mechanism and Operation

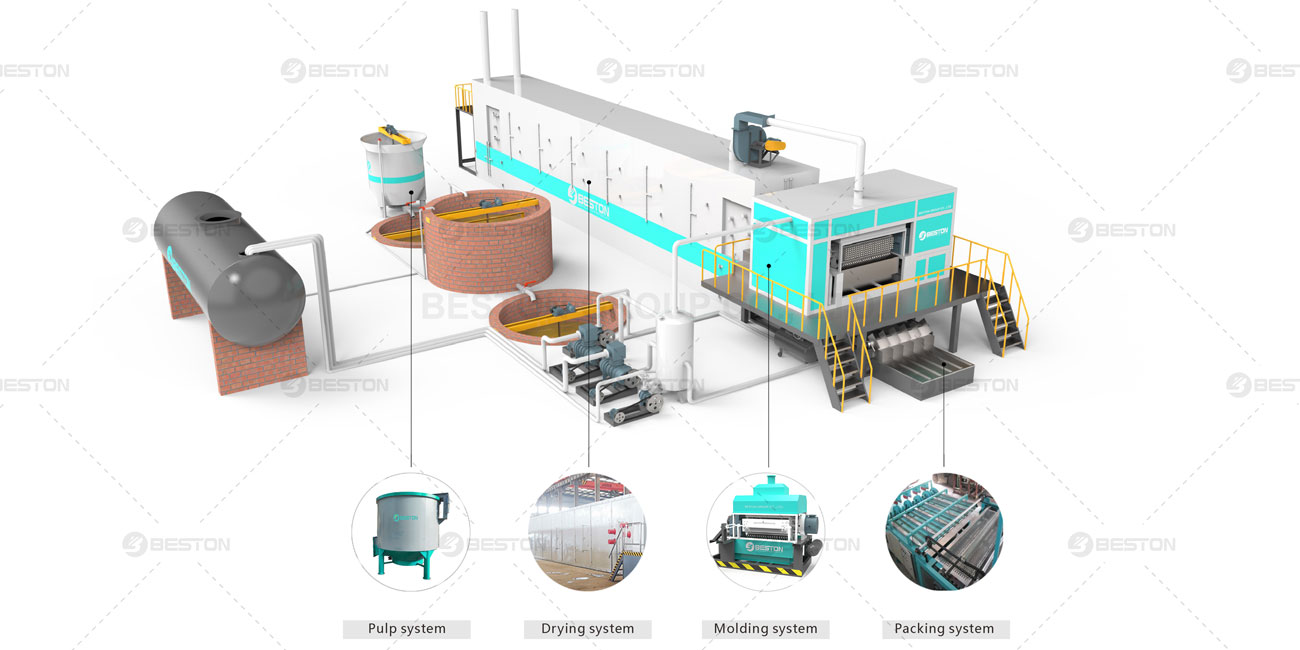

All three machines operate on the same basic principles. They employ a combination of pulping, forming, drying, and finishing processes to create molded fiber products. The production process begins with the preparation of raw materials, typically recycled paper or pulp. This material is mixed with water to form a slurry.

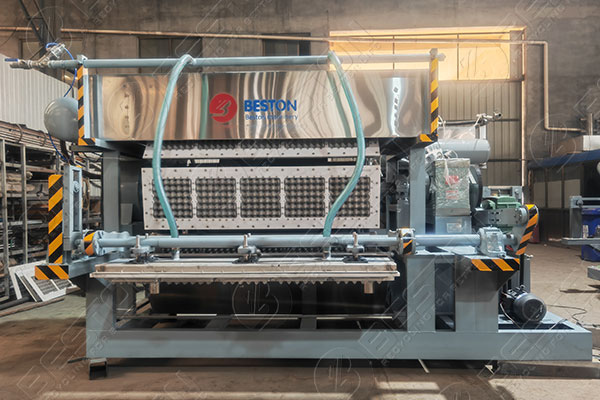

The slurry is then fed into the forming machine, where it is shaped into the desired tray or carton design using specific molds. Each machine may have its own set of molds tailored to create unique designs suitable for their respective end products. For example:

- The egg tray machine utilizes molds specifically designed to hold eggs securely, ensuring their safety during transport and storage.

- The egg carton machine is equipped with molds that can accommodate individual egg shapes, allowing for a more compact and protective packaging solution.

- The apple tray machine features molds designed to cradle apples, minimizing bruising and damage while maximizing airflow during transportation.

The Pulping Process

The initial step in the operation of these machines is the pulping process. This stage involves breaking down recycled paper products into a slurry. The quality of the pulp significantly impacts the final product. A well-prepared pulp mixture is essential for producing strong and durable trays and cartons. Adjustments to the pulp’s consistency can be made based on the specific requirements of the intended product.

Forming and Drying Stages

After pulping, the slurry is transferred to the forming section of the machine. Here, the slurry is poured into the molds. A vacuum system often aids in drawing the slurry into the molds, ensuring an even distribution and proper formation. Once the molds are filled, they undergo a drying phase. This can be accomplished through natural drying methods or using heat sources to speed up the process. The drying stage is crucial for achieving the desired strength and rigidity of the final product.

The drying method chosen can impact production efficiency and energy consumption. Utilizing energy-efficient drying technologies can enhance the overall sustainability of the manufacturing process. As industries increasingly focus on environmentally friendly practices, innovations in drying technologies are becoming more prevalent.

Finalizing the Product

Once dried, the formed trays or cartons are removed from the molds and undergo a finishing process. This may include trimming excess material, quality inspection, and packaging for shipment. Each machine can be equipped with additional features, such as automatic packing systems, to enhance efficiency.

Applications and Market Demand

The versatility of the egg tray machine, egg carton machine, and apple tray machine makes them highly valuable in various markets. Their products are essential for food packaging, especially in the agriculture sector. The growing demand for sustainable and biodegradable packaging options has further accelerated the need for such machinery.

With increased awareness of environmental issues, businesses are seeking alternatives to plastic packaging. Molded fiber products offer a sustainable solution, as they are typically made from recycled materials and are biodegradable. Consequently, the market for tray production machines is witnessing substantial growth.

Benefits of Using Molded Fiber Packaging

Molded fiber packaging, produced by these pulp molding machines, presents several advantages:

- Sustainability: Made from recycled paper, these products reduce waste and promote recycling.

- Biodegradability: Unlike plastic, molded fiber products decompose naturally, posing less risk to the environment.

- Protection: The cushioning properties of molded fiber provide excellent protection for delicate items like eggs and fruits.

- Customization: Manufacturers can customize molds to create products that meet specific market needs.

Technological Advancements

Recent advancements in technology have further enhanced the efficiency and effectiveness of these machines. Automation has become a key trend in the industry, allowing for increased production rates and reduced labor costs. Automated systems can monitor various stages of production, ensuring consistent quality and minimal downtime.

Moreover, innovations in machine design have improved energy efficiency. New models are designed to consume less energy while maintaining high production output. This not only lowers operating costs but also aligns with global sustainability goals.

Conclusion

In summary, the egg tray machine, egg carton machine, and apple tray machine are indeed variations of the same fundamental technology, differentiated primarily by their molds. Their shared operational principles, from pulping to forming and drying, underline their versatility in producing a range of molded fiber products.

As demand for sustainable packaging solutions continues to rise, these machines play a vital role in addressing environmental concerns while meeting market needs. Their ability to produce biodegradable, recycled packaging positions them at the forefront of modern packaging technology, contributing to a more sustainable future.